Description

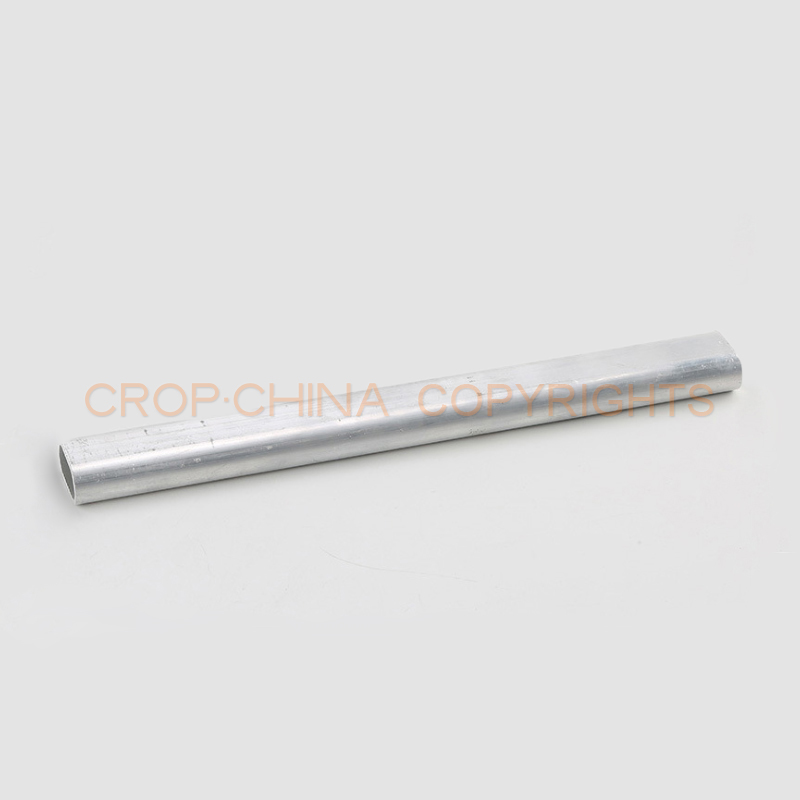

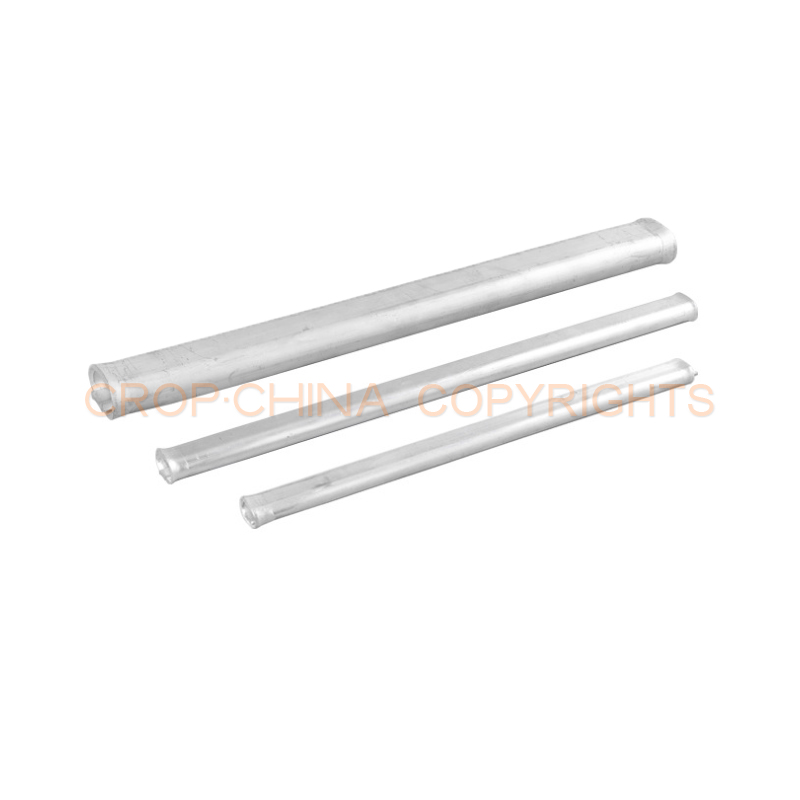

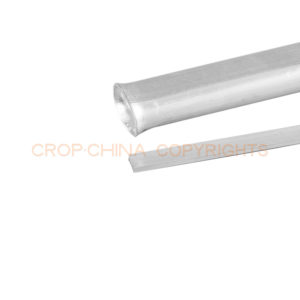

Mid span joint sleeve

Description

Mid span joint sleeve are also named automatic line splice,joint sleeve are used for splicing or repairing conductor of overhead transmission and distribution lines.tension joint provide a reliable,economical,and easy to install splicing method for overhead transmission and distribution lines.

Mid span joint sleeve connector for ACSR conductor not only satisfy the basic tension requirements, but also deal with the problems of “cold flow” of aluminum and the oxide file which forms on the strands.The DC resistance of cable sleeve must be less than that of the equi-length conductor,the temperature rise of all automatic line splice must be less than the splicing conductor.The slip strength of the splice connector must be less than 95% of the rated strength of conductor.

Features of joint sleeve

Easy to install,just for use with CRIMP tools only.

For ACSR,compact,5005,6201 and ACAR partial tension (40% tension rating) conductor jumper splicing.

Aluminum alloy conductor recommendations include 5005 and ACAR having the same diameter as a given ACSR conductor shown below. In addition, compressed (compact) conductor sizes within the same decimal conductor range are recommended.

Suitable conductor of automatic line splice

ACSR conductor

Material of line splice

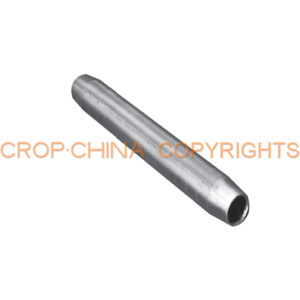

Sleeve of inner: hot dip galvanized steel

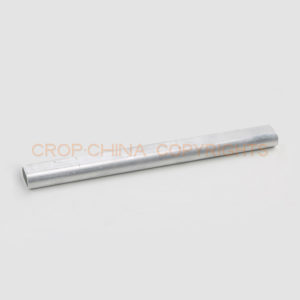

Sleeve of outer: Aluminum

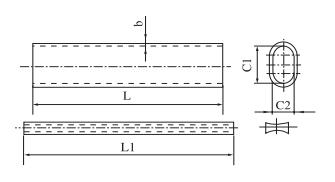

| Type | Suitable Conductor | Dimensions (mm) | Grip Strength (> kN) | ||||

|---|---|---|---|---|---|---|---|

| b | C1 | C2 | L | L1 | |||

| JT-10/2 | LGJ-10/2 | 1.7 | 11.0 | 5.0 | 170 | 180 | 3.9 |

| JT-16/3 | LGJ-16/3 | 1.7 | 14.0 | 6.0 | 210 | 220 | 5.8 |

| JT-25/4 | LGJ-25/4 | 1.7 | 16.0 | 7.8 | 270 | 280 | 8.8 |

| JT-35/6 | LGJ-35/6 | 2.1 | 18.0 | 8.8 | 340 | 350 | 12.0 |

| JT-50/8 | LGJ-50/8 | 2.3 | 22.0 | 10.5 | 420 | 430 | 16.0 |

| JT-70/10 | LGJ-70/10 | 2.6 | 26.0 | 12.5 | 500 | 510 | 22.0 |

| JT-95/15 | LGJ-95/15 | 2.6 | 31.0 | 15.0 | 690 | 700 | 33.0 |

| JT-95/20 | LGJ-95/20 | 2.6 | 31.5 | 15.2 | 690 | 700 | 35.0 |

| JT-120/7 | LGJ-120/7 | 3.1 | 33.0 | 16.0 | 910 | 920 | 26.0 |

| JT-120/20 | LGJ-120/20 | 3.1 | 35.0 | 17.0 | 910 | 920 | 39.0 |

| JT-150/8 | LGJ-150/8 | 3.1 | 36.0 | 17.5 | 940 | 950 | 31.0 |

| JT-150/20 | LGJ-150/20 | 3.1 | 37.0 | 18.0 | 940 | 950 | 44.0 |

| JT-150/25 | LGJ-150/25 | 3.1 | 39.0 | 19.0 | 940 | 950 | 51.0 |

| JT-185/10 | LGJ-185/10 | 3.4 | 40.0 | 19.5 | 1040 | 1050 | 39.0 |

| JT-185/25 | LGJ-185/25 | 3.4 | 43.0 | 21.0 | 1040 | 1050 | 56.0 |

| JT-185/30 | LGJ-185/30 | 3.4 | 43.0 | 21.0 | 1040 | 1050 | 61.0 |

| JT-210/10 | LGJ-210/10 | 3.6 | 43.0 | 21.0 | 1070 | 1080 | 43.0 |

| JT-210/25 | LGJ-210/25 | 3.6 | 45.0 | 21.5 | 1070 | 1080 | 63.0 |

| JT-210/35 | LGJ-210/35 | 3.6 | 46.0 | 22.0 | 1070 | 1080 | 71.0 |

| JT-240/30 | LGJ-240/30 | 3.9 | 48.0 | 23.5 | 540 | 550 | 72.0 |

| JT-240/40 | LGJ-240/40 | 3.6 | 48.0 | 23.5 | 540 | 550 | 79.0 |